Welcome to Hebei Takai Vehicle Parts Technology Co., Ltd.

What are the functions of engineering machinery filter cartridges?

Release Time:

Sep 11,2023

The function of the engineering machinery filter element is to effectively filter impurities in the engine oil, reduce the flow resistance of the engine oil, ensure lubrication, and minimize the wear of various components during operation

1. The role of the "three cores"

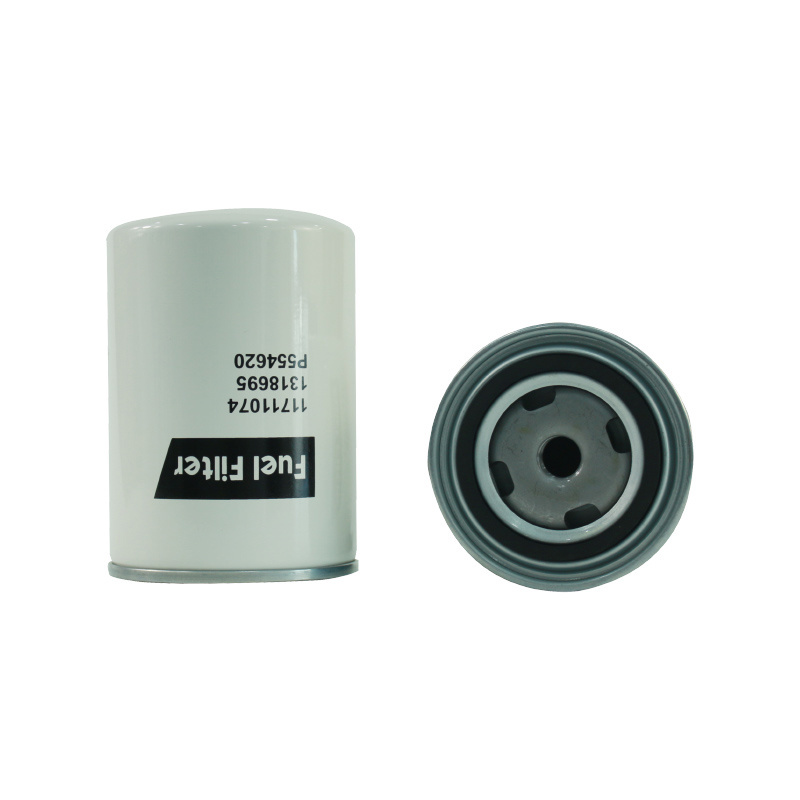

The function of the engineering machinery filter element is to effectively filter impurities in the engine oil, reduce the flow resistance of the engine oil, ensure lubrication, and minimize the wear of various components during operation; The function of the fuel filter is to effectively filter out impurities such as dust, iron filings, metal oxides, and oil sludge in the fuel, prevent blockage of the fuel system, improve combustion efficiency, and ensure stable engine operation; The air filter is located in the intake system of the engine, and its main function is to filter out harmful impurities in the air that will enter the cylinder, in order to reduce early wear of the cylinder, piston, piston ring, valve and valve seat, thereby providing assurance for the normal operation and output power of the engine.

The results show that the wear of the engine mainly includes corrosion wear, contact wear, and abrasive wear, with abrasive wear accounting for 60% to 70% of the wear amount. Engineering machinery filter cartridges typically operate in a very harsh environment, and without proper protection, the engine's cylinders and piston rings will quickly wear out. The main function of the "three cores" is to effectively filter air, oil, and fuel, reduce abrasive damage to the engine, and ensure engine operating efficiency.

2. Replacement cycle of "three cores"

Normally, the replacement cycle for the engine oil filter is 50 hours of operation for the first time, followed by every 300 hours of operation thereafter; The replacement cycle of the fuel filter is the first 100 hours of operation, and then every 300 hours of operation. The replacement cycle can be appropriately extended or shortened based on the difference in the quality level of the oil and fuel being filled; The replacement cycle of the engineering machinery filter and air filter used by different models varies, mainly adjusting the replacement cycle of the air filter according to the air quality of the working environment, and the inner and outer filter elements must be replaced together. It is worth mentioning that it is not recommended to use compressed air quality data for development and cleaning of air filter elements, as high-pressure airflow can damage the filter paper and affect the efficiency of engineering machinery filter elements.

You Can Also Learn More About Industry Trends