Welcome to Hebei Takai Vehicle Parts Technology Co., Ltd.

Understanding High Pressure Common Rail Fuel Systems: A Key Component in Modern Diesel Engines

Release Time:

Jun 10,2025

High pressure common rail fuel systems have become a cornerstone in modern diesel engine technology, offering enhanced efficiency, reduced emissions, and improved performance. This system is designed to deliver fuel at high pressure to the injectors, allowing for precise control over the combustion process. Understanding the mechanics and benefits of these systems is essential for professionals in

High pressure common rail fuel systems have become a cornerstone in modern diesel engine technology, offering enhanced efficiency, reduced emissions, and improved performance. This system is designed to deliver fuel at high pressure to the injectors, allowing for precise control over the combustion process. Understanding the mechanics and benefits of these systems is essential for professionals in the automotive industry, particularly those involved in fuel filtration and fuel management.

At the heart of the high pressure common rail system is its ability to store fuel at high pressure within a common rail, which is a single reservoir that supplies fuel to multiple injectors. This setup allows for multiple injection events per combustion cycle, optimizing fuel delivery and improving combustion efficiency. Unlike traditional diesel fuel systems that inject fuel directly into the combustion chamber at a single point, the common rail system enables varying injection timings and durations, which leads to better atomization of the fuel and more complete combustion.

One of the key advantages of high pressure common rail fuel systems is their flexibility in controlling fuel delivery. By varying the pressure and timing of the fuel injectors, these systems can adapt to changing engine demands, resulting in smoother operation and enhanced power output. Additionally, they help minimize diesel knock and reduce particulate emissions, contributing to compliance with stringent environmental regulations.

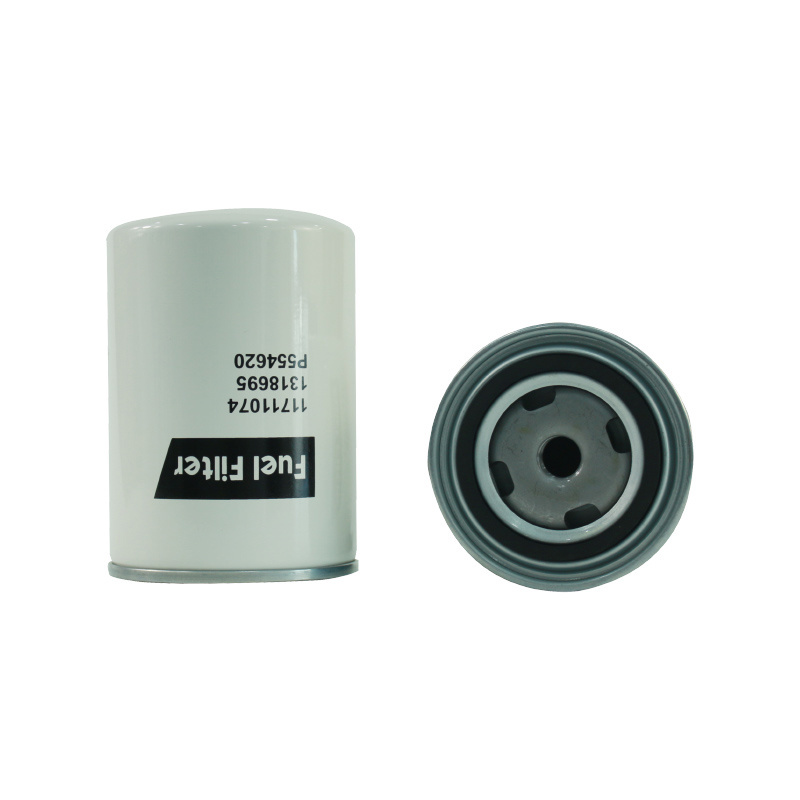

However, the effectiveness of high pressure common rail systems heavily relies on the quality of fuel and filtration. Contaminants such as dirt, water, and particulates can cause significant damage to the injectors and the common rail itself, leading to performance issues and costly repairs. This is where fuel filters play a crucial role. High-quality fuel filters are essential in removing contaminants before they enter the system, ensuring the longevity and efficiency of the high pressure common rail fuel system.

Maintenance of high pressure common rail systems should include regular inspections of fuel filters and timely replacement as needed. Additionally, using quality fuel that meets industry standards will help prevent issues related to contamination. It’s also advisable for professionals to stay informed about advancements in fuel filtration technology and practices to optimize performance and reliability.

In conclusion, the high pressure common rail fuel system is a sophisticated and efficient technology that has transformed diesel engine performance. For automotive professionals focusing on fuel filters, understanding the dynamics of this system is crucial. By ensuring the integrity of fuel delivery and filtration, you can contribute to the overall efficiency and reliability of modern diesel engines, ultimately leading to enhanced customer satisfaction and trust in automotive services.

At the heart of the high pressure common rail system is its ability to store fuel at high pressure within a common rail, which is a single reservoir that supplies fuel to multiple injectors. This setup allows for multiple injection events per combustion cycle, optimizing fuel delivery and improving combustion efficiency. Unlike traditional diesel fuel systems that inject fuel directly into the combustion chamber at a single point, the common rail system enables varying injection timings and durations, which leads to better atomization of the fuel and more complete combustion.

One of the key advantages of high pressure common rail fuel systems is their flexibility in controlling fuel delivery. By varying the pressure and timing of the fuel injectors, these systems can adapt to changing engine demands, resulting in smoother operation and enhanced power output. Additionally, they help minimize diesel knock and reduce particulate emissions, contributing to compliance with stringent environmental regulations.

However, the effectiveness of high pressure common rail systems heavily relies on the quality of fuel and filtration. Contaminants such as dirt, water, and particulates can cause significant damage to the injectors and the common rail itself, leading to performance issues and costly repairs. This is where fuel filters play a crucial role. High-quality fuel filters are essential in removing contaminants before they enter the system, ensuring the longevity and efficiency of the high pressure common rail fuel system.

Maintenance of high pressure common rail systems should include regular inspections of fuel filters and timely replacement as needed. Additionally, using quality fuel that meets industry standards will help prevent issues related to contamination. It’s also advisable for professionals to stay informed about advancements in fuel filtration technology and practices to optimize performance and reliability.

In conclusion, the high pressure common rail fuel system is a sophisticated and efficient technology that has transformed diesel engine performance. For automotive professionals focusing on fuel filters, understanding the dynamics of this system is crucial. By ensuring the integrity of fuel delivery and filtration, you can contribute to the overall efficiency and reliability of modern diesel engines, ultimately leading to enhanced customer satisfaction and trust in automotive services.

You Can Also Learn More About Industry Trends