Welcome to Hebei Takai Vehicle Parts Technology Co., Ltd.

Understanding Tractor Oil Filters: Essential Components for Optimal Engine Performance

Release Time:

Aug 09,2025

When it comes to the operation and longevity of tractors, one component that often goes overlooked is the oil filter. Tractor oil filters play an essential role in ensuring the engine runs smoothly and efficiently. Their primary function is to remove impurities from the engine oil, which can include dirt, metal particles, and other contaminants that can accumulate over time. This process is vital

When it comes to the operation and longevity of tractors, one component that often goes overlooked is the oil filter. Tractor oil filters play an essential role in ensuring the engine runs smoothly and efficiently. Their primary function is to remove impurities from the engine oil, which can include dirt, metal particles, and other contaminants that can accumulate over time. This process is vital for maintaining the overall health of the engine, as clean oil is crucial for lubrication, heat dissipation, and preventing wear and tear on engine components.

Tractor oil filters operate using a simple yet effective mechanism. Engine oil is drawn from the oil pan and is directed through the oil filter, where it passes through a filtration medium. This medium captures particles and contaminants, allowing only clean oil to return to the engine. The effectiveness of this filtration process can significantly impact engine performance and efficiency. A clogged or dirty oil filter can restrict oil flow, leading to increased engine wear, overheating, and potentially catastrophic engine failure.

Regular maintenance of tractor oil filters is essential for optimal performance. It is generally recommended to replace the oil filter during every oil change, which is typically every 100-250 hours of operation, depending on the manufacturer's guidelines and the operating conditions of the tractor. Neglecting this routine maintenance can lead to a buildup of contaminants within the oil, ultimately resulting in diminished engine performance and a shorter lifespan for the tractor.

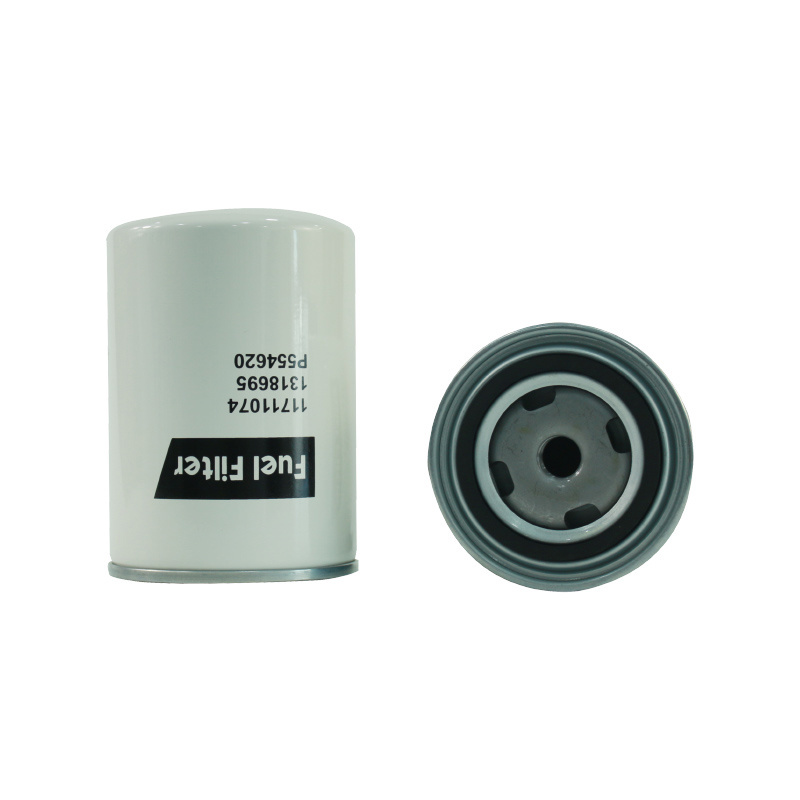

There are various types of tractor oil filters available on the market, including spin-on filters and cartridge filters. Spin-on filters are designed for easy installation and replacement, while cartridge filters may require more effort to replace but can offer enhanced filtration capabilities. Each type has its own set of benefits, and the choice often depends on the specific needs of the tractor and the preferences of the operator.

Another important aspect to consider is the quality of the oil filter. High-quality filters often use advanced filtration media that can capture smaller particles and provide better protection for the engine. It's essential to choose filters that meet or exceed the specifications recommended by the tractor manufacturer to ensure compatibility and performance.

In conclusion, tractor oil filters are a vital component of agricultural machinery that should not be overlooked. By understanding their function and maintaining them properly, tractor operators can ensure their engines run efficiently and reliably. Regular oil filter changes can prevent costly repairs and extend the lifespan of the equipment, ultimately leading to better productivity on the farm.

Tractor oil filters operate using a simple yet effective mechanism. Engine oil is drawn from the oil pan and is directed through the oil filter, where it passes through a filtration medium. This medium captures particles and contaminants, allowing only clean oil to return to the engine. The effectiveness of this filtration process can significantly impact engine performance and efficiency. A clogged or dirty oil filter can restrict oil flow, leading to increased engine wear, overheating, and potentially catastrophic engine failure.

Regular maintenance of tractor oil filters is essential for optimal performance. It is generally recommended to replace the oil filter during every oil change, which is typically every 100-250 hours of operation, depending on the manufacturer's guidelines and the operating conditions of the tractor. Neglecting this routine maintenance can lead to a buildup of contaminants within the oil, ultimately resulting in diminished engine performance and a shorter lifespan for the tractor.

There are various types of tractor oil filters available on the market, including spin-on filters and cartridge filters. Spin-on filters are designed for easy installation and replacement, while cartridge filters may require more effort to replace but can offer enhanced filtration capabilities. Each type has its own set of benefits, and the choice often depends on the specific needs of the tractor and the preferences of the operator.

Another important aspect to consider is the quality of the oil filter. High-quality filters often use advanced filtration media that can capture smaller particles and provide better protection for the engine. It's essential to choose filters that meet or exceed the specifications recommended by the tractor manufacturer to ensure compatibility and performance.

In conclusion, tractor oil filters are a vital component of agricultural machinery that should not be overlooked. By understanding their function and maintaining them properly, tractor operators can ensure their engines run efficiently and reliably. Regular oil filter changes can prevent costly repairs and extend the lifespan of the equipment, ultimately leading to better productivity on the farm.

You Can Also Learn More About Industry Trends