Welcome to Hebei Takai Vehicle Parts Technology Co., Ltd.

Hydraulic Oil Filter Replacement: A Step-by-Step Guide for Optimal Performance

Release Time:

May 08,2025

Hydraulic Oil Filter Replacement: A Step-by-Step Guide for Optimal Performance Table of Contents 1. Introduction to Hydraulic Oil Filters 2. Importance of Regular Filter Replacement 3. Tools Required for Hydraulic Oil Filter Replacement 4. Step-by-Step Guide to Replacing Hydraulic Oil Filters 4.1 Preparation Before Replacement 4.2 Removing the Old Filter 4.3 Install

Hydraulic Oil Filter Replacement: A Step-by-Step Guide for Optimal Performance

Table of Contents

- 1. Introduction to Hydraulic Oil Filters

- 2. Importance of Regular Filter Replacement

- 3. Tools Required for Hydraulic Oil Filter Replacement

- 4. Step-by-Step Guide to Replacing Hydraulic Oil Filters

- 4.1 Preparation Before Replacement

- 4.2 Removing the Old Filter

- 4.3 Installing the New Filter

- 4.4 Final Checks After Replacement

- 5. Maintenance Tips for Hydraulic Systems

- 6. Common Issues and Troubleshooting Tips

- 7. FAQs About Hydraulic Oil Filter Replacement

- 8. Conclusion

1. Introduction to Hydraulic Oil Filters

Hydraulic oil filters are crucial components in any hydraulic system. They serve the primary purpose of removing contaminants from hydraulic fluid, ensuring that the system operates smoothly and efficiently. In industrial settings, the reliability of hydraulic systems is paramount, and regular maintenance, including filter replacement, is essential to prolong the life of equipment and prevent costly downtimes.

2. Importance of Regular Filter Replacement

Replacing hydraulic oil filters at regular intervals is vital for several reasons:

- **Contaminant Removal**: Filters trap dirt, debris, and other pollutants that could damage components.

- **System Efficiency**: Clean oil ensures optimal performance of hydraulic systems, reducing wear and tear.

- **Cost Savings**: Regular maintenance helps avoid unexpected breakdowns and costly repairs, providing significant savings in the long run.

3. Tools Required for Hydraulic Oil Filter Replacement

Before embarking on the replacement process, gather the following tools and materials:

- **Wrenches**: To loosen and remove the filter.

- **Oil catch pan**: To collect any oil that spills during the replacement.

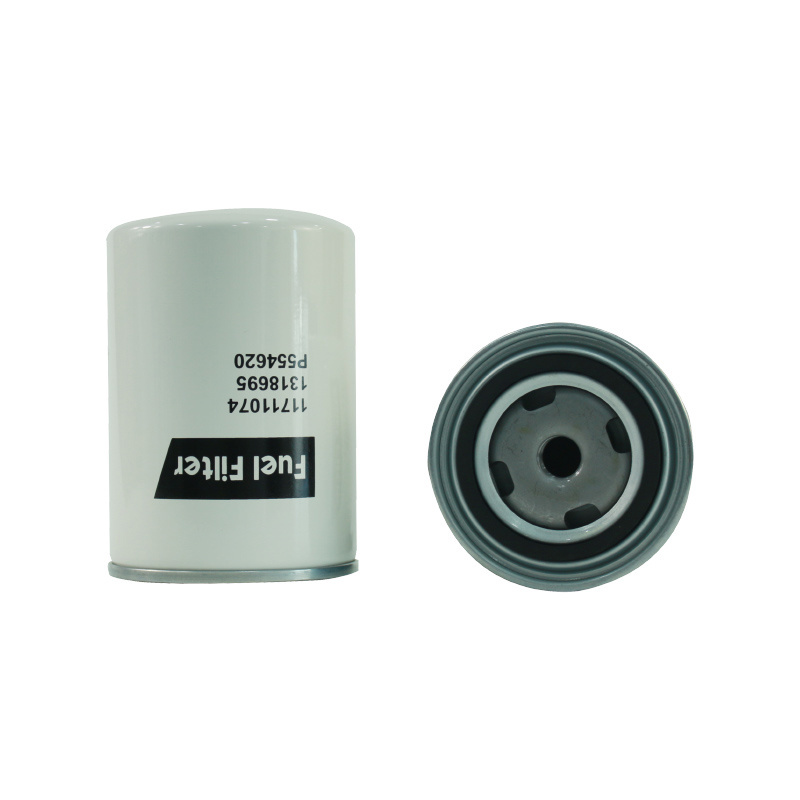

- **New filter**: Ensure it meets the specifications of your hydraulic system.

- **Rags**: For cleaning up spills and wiping down surfaces.

- **Safety gloves and goggles**: To protect yourself from hydraulic fluid and sharp objects.

4. Step-by-Step Guide to Replacing Hydraulic Oil Filters

4.1 Preparation Before Replacement

Before starting the replacement process, it’s essential to follow these preparatory steps:

1. **Turn Off Equipment**: Ensure the hydraulic system is powered down and safely isolated.

2. **Release Pressure**: Locate the release valve to relieve any residual pressure in the hydraulic system.

3. **Clean Around the Filter**: Use a rag to clean the area around the filter, preventing contaminants from entering the system during removal.

4.2 Removing the Old Filter

Once you have prepared the area, follow these steps to remove the old filter:

1. **Position the Oil Catch Pan**: Place it under the filter to catch any hydraulic fluid that may spill.

2. **Loosen the Filter**: Use a wrench or your hands to unscrew the filter counterclockwise. Be cautious as some oil may spill out.

3. **Remove the Filter**: Once loosened, remove the filter completely and allow any remaining oil to drain into the pan.

4.3 Installing the New Filter

With the old filter removed, it’s time to install the new one:

1. **Prepare the New Filter**: Apply a thin layer of new hydraulic oil to the rubber O-ring of the new filter; this helps create a better seal.

2. **Screw on the New Filter**: Align the filter with the mounting hole and hand-tighten it clockwise.

3. **Secure the Filter**: Use a wrench to tighten it another quarter turn, ensuring it is snug but not over-tightened.

4.4 Final Checks After Replacement

After installing the new filter, it’s crucial to perform these checks:

1. **Check for Leaks**: Start the hydraulic system and inspect the filter area for leaks.

2. **Monitor Performance**: Observe the system for any unusual noises or performance issues.

3. **Dispose of Old Filter**: Properly dispose of the old filter and any spilled hydraulic fluid according to local regulations.

5. Maintenance Tips for Hydraulic Systems

To ensure the longevity and efficiency of your hydraulic systems, consider these maintenance tips:

- **Regular Inspections**: Schedule periodic inspections of your hydraulic system to identify potential issues early.

- **Fluid Quality**: Monitor the quality of hydraulic fluid regularly and replace it as necessary.

- **Keep Components Clean**: Maintain cleanliness in and around hydraulic components to reduce the risk of contamination.

6. Common Issues and Troubleshooting Tips

Despite regular maintenance, issues can arise. Here are some common problems and their solutions:

- **Low Pressure**: Check for leaks in the system or signs of a clogged filter.

- **Overheating**: This may indicate low fluid levels or a malfunctioning cooling system.

- **Strange Noises**: Unusual sounds can suggest internal damage; immediate inspection is recommended.

7. FAQs About Hydraulic Oil Filter Replacement

**Q1: How often should I replace my hydraulic oil filter?**

A1: Replacement frequency depends on usage and the manufacturer’s recommendations, but generally, every 200 to 400 hours of operation is common.

**Q2: Can I use any filter for my hydraulic system?**

A2: No, always use filters that meet your system's specifications to ensure proper function.

**Q3: What happens if I don’t replace the filter?**

A3: Failing to replace the filter can lead to contamination, reduced efficiency, and potential system failure.

**Q4: How can I tell if my hydraulic filter is clogged?**

A4: Signs include decreased pressure, overheating, and unusual noises from the hydraulic system.

**Q5: Is it safe to replace the hydraulic oil filter myself?**

A5: Yes, if you follow proper safety precautions and guidelines, replacing the filter can be safely done by individuals with basic mechanical knowledge.

8. Conclusion

Replacing hydraulic oil filters is an essential maintenance task that ensures the efficiency and longevity of your hydraulic systems. By following the step-by-step guide outlined in this article, you can confidently perform the replacement process, minimizing the risk of equipment failure and costly downtime. Regular maintenance, including timely filter replacements, is the key to keeping your industrial equipment running smoothly. Always prioritize safety and proper procedures to achieve optimal performance from your hydraulic systems.

You Can Also Learn More About Industry Trends