Welcome to Hebei Takai Vehicle Parts Technology Co., Ltd.

Optimizing Fuel Filtration for Dump Trucks: Best Practices for Enhanced Performance

Release Time:

May 14,2025

Optimizing Fuel Filtration for Dump Trucks: Best Practices Table of Contents Understanding Fuel Filtration in Dump Trucks The Importance of Fuel Filtration for Optimal Performance Types of Fuel Filters Used in Dump Trucks Best Practices for Fuel Filtration Maintenance How to Choose the Right Fuel Filter Monitoring Fuel Quality for Better Filtration Common Fuel Filtration Issues and

Optimizing Fuel Filtration for Dump Trucks: Best Practices

Table of Contents

- Understanding Fuel Filtration in Dump Trucks

- The Importance of Fuel Filtration for Optimal Performance

- Types of Fuel Filters Used in Dump Trucks

- Best Practices for Fuel Filtration Maintenance

- How to Choose the Right Fuel Filter

- Monitoring Fuel Quality for Better Filtration

- Common Fuel Filtration Issues and Solutions

- Frequently Asked Questions (FAQs)

- Conclusion

Understanding Fuel Filtration in Dump Trucks

Fuel filtration is a critical component of dump truck operation. It involves the removal of contaminants from fuel to ensure the smooth functioning of the engine. Contaminants, such as dirt, rust, and water, can cause significant damage to engines, leading to costly repairs and downtime. Therefore, understanding the fuel filtration process and its importance is the first step in optimizing performance.

The Importance of Fuel Filtration for Optimal Performance

Effective fuel filtration plays a vital role in maintaining the efficiency and longevity of dump trucks. Here are some key reasons why proper fuel filtration is essential:

1. Protects Engine Components

A clean fuel supply ensures that engine components, such as injectors and pumps, operate efficiently. Contaminated fuel can lead to wear and tear, resulting in premature engine failure.

2. Improves Fuel Efficiency

Clean fuel burns more efficiently, resulting in better fuel economy. This translates to reduced operational costs for dump truck owners.

3. Minimizes Downtime

By preventing fuel-related issues, effective filtration reduces the likelihood of engine breakdowns, leading to less downtime and greater productivity.

4. Extends Equipment Lifespan

Regular fuel filtration maintenance extends the lifespan of dump trucks by protecting crucial engine components from damage caused by impurities.

Types of Fuel Filters Used in Dump Trucks

When it comes to fuel filtration, several types of filters are commonly used in dump trucks:

1. Primary Fuel Filters

Primary fuel filters are the first line of defense against contaminants. They typically have a larger filtration area and are designed to trap larger particles.

2. Secondary Fuel Filters

Secondary fuel filters provide an additional layer of protection by filtering out finer particles that may have passed through the primary filter. This helps ensure that only clean fuel reaches the engine.

3. Water Separators

Water separators are crucial for preventing water from entering the fuel system. They remove moisture from the fuel, which can cause corrosion and other issues within the engine.

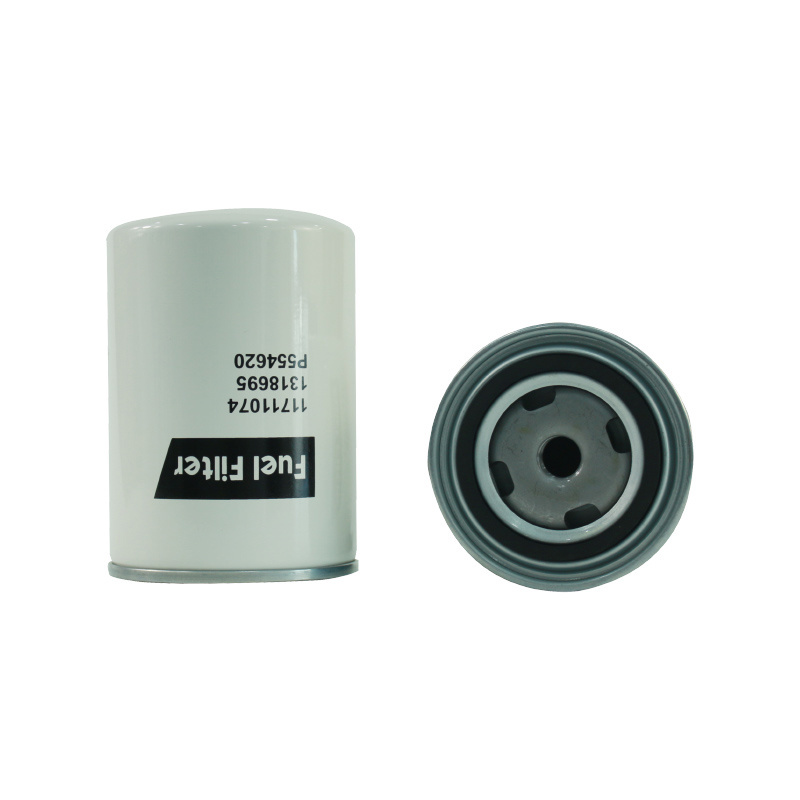

4. Spin-On Fuel Filters

Spin-on filters are easy to replace and are commonly found in many dump trucks. They offer a convenient solution for routine maintenance.

Best Practices for Fuel Filtration Maintenance

To optimize fuel filtration in dump trucks, implementing best practices is essential. Here are some key strategies:

1. Regular Filter Replacement

Establish a regular schedule for replacing fuel filters based on the manufacturer’s recommendations. Frequent filter changes prevent clogging and ensure optimal fuel flow.

2. Monitor Fuel Quality

Regularly check fuel quality to detect any impurities or water content. Conduct tests for sediment and microbial contamination to maintain high fuel standards.

3. Maintain Clean Fuel Tanks

Ensure that fuel tanks are clean and free from rust, dirt, and debris. Regularly inspect and clean tanks to prevent contaminants from entering the fuel system.

4. Implement Fuel Additives

Consider using fuel additives that enhance fuel quality and improve filtration. These additives can help disperse water and prevent microbial growth.

5. Conduct Periodic Inspections

Perform routine inspections of the fuel filtration system. Look for signs of wear or damage to filters, hoses, and connections. Address any issues promptly.

How to Choose the Right Fuel Filter

Choosing the right fuel filter is crucial for efficient filtration. Here are some factors to consider:

1. Compatibility with Engine Type

Ensure that the filter is compatible with the specific make and model of the dump truck. Check specifications to confirm the correct fit.

2. Filtration Rating

Review the filtration rating of the filter, which indicates its effectiveness at removing impurities. Opt for filters with lower micron ratings for finer filtration.

3. Flow Rate

Consider the flow rate of the filter to ensure that it can handle the engine’s fuel demands without causing restrictions.

4. Brand Reputation

Choose filters from reputable manufacturers known for producing high-quality products. This can make a significant difference in performance and reliability.

Monitoring Fuel Quality for Better Filtration

Monitoring fuel quality is essential for optimizing the filtration process. Here are some effective methods:

1. Fuel Testing Kits

Utilize fuel testing kits to assess fuel quality regularly. These kits can identify contaminants, water, and microbial growth, allowing for timely intervention.

2. Visual Inspection

Perform visual inspections of fuel before filling the tanks. Look for any discoloration or sediment, indicating potential contamination.

3. Regular Sampling

Take fuel samples from different sources and analyze them for purity. This practice can help identify any issues before they affect the filtration system.

Common Fuel Filtration Issues and Solutions

Understanding common fuel filtration issues can help you take proactive measures. Here are some typical problems and their solutions:

1. Clogged Filters

Clogged filters can restrict fuel flow, leading to engine performance issues. **Solution**: Replace filters according to the recommended schedule and consider using pre-filters to catch larger debris.

2. Water Contamination

Water in fuel can cause corrosion and engine damage. **Solution**: Install water separators and regularly drain accumulated water from fuel tanks.

3. Microbial Contamination

Microbial growth can lead to sludge formation, affecting fuel quality. **Solution**: Use biocides in fuel and maintain clean storage tanks to prevent growth.

4. Improper Filter Installation

Incorrectly installed filters can lead to leaks and reduced efficiency. **Solution**: Follow manufacturer guidelines for installation and regularly check for proper fit.

Frequently Asked Questions (FAQs)

1. How often should I change the fuel filters in my dump truck?

It’s recommended to change fuel filters based on the manufacturer’s guidelines, typically every 10,000 to 15,000 miles or at least once a year, depending on usage.

2. Can I clean and reuse fuel filters?

While some filters can be cleaned and reused, it’s generally more effective to replace them to ensure optimal filtration performance.

3. What are the signs of a clogged fuel filter?

Signs include decreased engine performance, difficulty starting, and reduced fuel efficiency. If you notice these symptoms, check and replace the fuel filter.

4. How do I prevent water contamination in fuel?

Regularly inspect fuel tanks, use water separators, and ensure tight seals on fuel caps to prevent moisture intrusion.

5. What type of fuel filter is best for my dump truck?

The best fuel filter depends on your specific engine requirements. Consult your truck’s manufacturer for recommendations based on your vehicle’s specifications.

Conclusion

Optimizing fuel filtration for dump trucks is essential for ensuring peak performance, longevity, and efficiency. By understanding the importance of fuel filtration, implementing best practices, and choosing the right filters, dump truck operators can significantly enhance their equipment's reliability. Regular maintenance, monitoring fuel quality, and addressing common filtration issues will lead to reduced downtime and operational costs. By following these guidelines, we can ensure that our dump trucks remain in top condition, performing efficiently for years to come.

You Can Also Learn More About Industry Trends